MacLellan Rubber is commonly faced with the query 'your competitor's material is better because it has a higher operating temperature'. When clarified, we often find that the technical datasheet being referred to exaggerates the maximum operating temperature, as defined by compound manufacturers, by listing the intermittent peak as being the constant operating temperature.

Why gaskets and seals are run at temperatures above the recommended maximum:

There are generally three reasons why gaskets and seals are run at temperatures above the recommended maximum:

- There is a failure in the operating system causing conditions to exceed stated parameters.

- The maximum operating temperature in the technical data is misinterpreted as Continuous rather tan Intermittent.

- The maximum operating temperature is misrepresented by the manufacturer.

Failures through criteria 1 are a hazard of manufacture and can be mitigated through good systems and regular maintenance.

Failures through criteria 2 are more about education of both end user - often reading what they want to see - and the supplier clearly differentiating between continuous operating temperature and intermittent, short peaks.

Failures through criteria 3 are representative of a poor supplier with little technical knowledge and can often be a deliberate attempt to gain business in an unscrupulous manner.

The implications of installing a gasket material with a true constant operating temperature below that stated are no different from installing a gasket unsuitable for the media or pressure; it will fail and, depending on how far above the recommended constant you are operating, the quicker it will fail.

Heat Resistance of FKM:

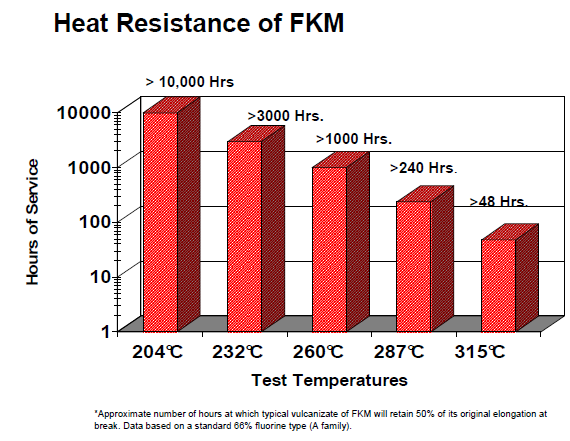

A clear example of the shortening of working life is shown in tests undertaken on

Viton™ A (our

A075 grade) material, see image below, where running significantly below the recommended constant temperature of 204

�C will give an expected working life of a gasket or seal of approximately 10,000 hours.

Accelerate that to the more typically quoted 250

°C for

Viton™ A and the working life drops to approximately 2,000 hours. Take that to 275

°C, as advised by one sheet supplier, and the working life drops to approximately 500 hours. Take it to 315

°C or beyond and working life is only a few hours.

What happens to the material causing the failure?

Running at excessive temperatures has several effects on the material. The material will appear to harden then crumble, and this is often called embrittlement where essentially you are overcooking the material.

As a consequence, the material will lose elasticity and become permanently compressed, which means the material is not acting against the flange faces to create an effective seal, resulting in leak paths.

For a supplier you can trust to provide you with accurate datasheets and technical support to help ensure you select the right material for your end-user requirements, speak to the MacLellan Rubber team.