It's a common misconception that there is only one grade of

Viton™, and being a high grade, high priced, specialist

Polymer, it is suitable for all those applications that other lesser materials can't support.

Viton™ is suitable for a range of applications

The reality is that

Viton™ has many derivations for a broad range of technically challenging applications; some are subtly different whilst others are designed for dramatically divergent environments. Selecting the wrong grade can be as disastrous as using a more commercial material.

We typically look at

Viton™ compounds for:

- chemical or hydrocarbon resistance at elevated temperatures;

- flexibility at very low temperatures; and

- general performance in extreme environments.

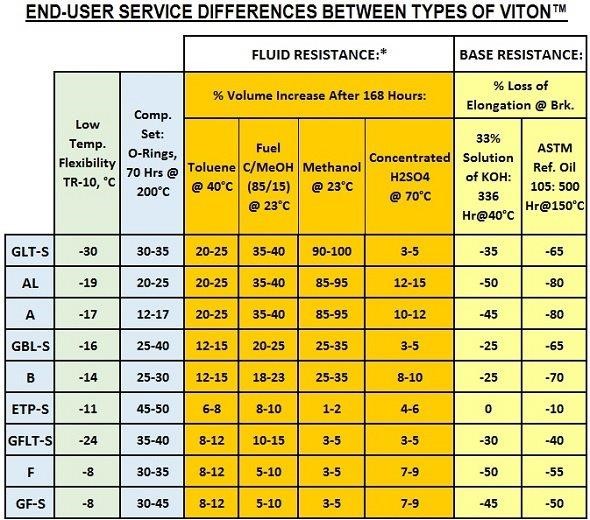

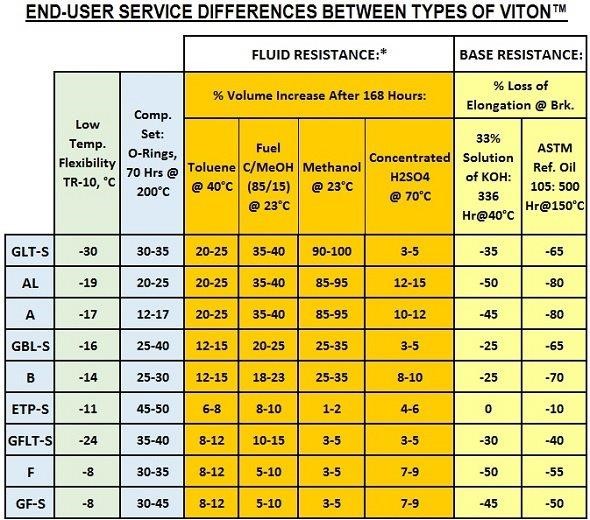

However, with differences in volume swell performance showing a factor of 50:1 between some grades, and loss of elongation at break showing a factor of 8:1, selecting the right grade needs to be a considered choice.

The difference in performance between different types of Viton™

The chart below gives an example of the dramatic differences in performance with common chemical compounds against which

Viton™ is selected for service. Many users will look no further than

Viton™ A - this being commonly available in Roll or Sheet format from stock - however, if the application is Toulene based and requires a controlled volume swell of less than 10%,

Viton™ ETP-S is the only material of choice. This is even more significant when looking at Methanol rich applications where

Viton™ A will swell approximately 90% versus 30% for

Viton™ B and only 5% for

Viton™ F. Conversely, with applications requiring low compression set at higher temperatures,

Viton™ A is the best material selection.

Viton">

Technical advice and support in choosing the correct Viton™

As with all polymers, the universal name covers a multitude of grades and technical performance criteria - commercial materials are commonly not differentiated from British or European standards - and at MacLellan Rubber, we see many general material requests which become technical or commercial problems later. Taking time to consider the application and operating conditions can often seem tedious when you're trying to get a quotation or job done, but is invaluable to getting it done right, first time.

As

Chemours partners, MacLellan Rubber offer technical advice and support in guiding you through this selection process and we work with Chemours to ensure the advice we offer is accurate and up to date, safeguarding your products and your reputation.

Call our expert Technical Team on 01902 30 77 11 for help selecting the right

Viton™ for end user applications.

Viton">

Viton">