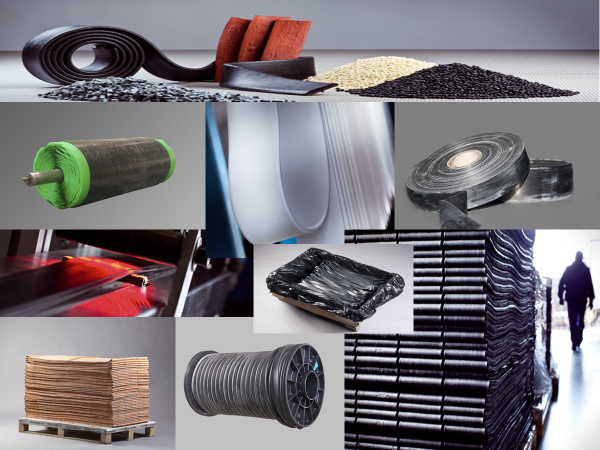

What is Rubber Lining?

Rubber lining is a rubber sheet or membrane applied to the internal surface of a containment system and pipework to protection the metal from corrosion in aggressive chemical or temperature environments. A Rubber Lining is required to demonstrate resistance to either acid, chemicals and alkalis, provide abrasion resistance, or biological protection.

Typical uses of Rubber Linings

Rubber linings are used in a wide range of industrial applications where they both protect the metal containment vessels and pipework from corrosion and the media being stored or transported from being contaminated by impurities from any chemical reaction with the metal. Linings are produced in different thicknesses to be used in a variety of industrial situations where they are designed to extend the working life of the plant and equipment by resisting chemical attack or providing severe abrasion resistance.

Natural Soft Rubbers are widely used for pickling tanks and storage tanks or for slurry tank, pipe and pump lining. These materials typically have a low hardness, high flexibility and good resistance to abrasion.

Hard Synthetic Rubber linings are used for storage tanks, reactors, and pipelines with higher operating temperatures, and demonstrate good chemical and impact resistance whilst retaining flexibility,

Materials and their Applications

MacLellan offer a range of un-cured and cured lining materials, which can be vulcanised or bonded in-situ.

Our materials are all European manufactured to the highest quality standards with complete traceability and batch tested every 150kg for guaranteed consistency of performance.

Common Lining materials will include:

Natural Rubber – High quality Natural Rubber has excellent wear characteristics in lining applications and is widely used in the waste and slurry industry to protect pipes and vessels, and in the mining sector to line chutes, hoppers, separators and sand washers.

Neoprene Rubber - Chloroprene rubber demonstrates good weathering and ozone cracking

resistance as well as oil, acid and abrasion resistance. Widely used for

desalination plants, sea water piping, lining for water box, site joints of

CWP, vessels etc.

Butyl Rubber - Isobutylene Isoprene

has excellent chemical resistance at high temperatures and is also very durable

due to the inherent low vapor permeability. Butyl rubber linings are the

preferred choice for applications in vessels, pipes for acid plants, FGD,

hypochloride storage and transport.

Hypalon Rubber - Chlorosulfonated polyethylene rubber offer outstanding

chemical resistance to oxidizing acids at high concentrations. This is used in

vessels and pipes with high acid concentration.

EPDM Rubber – Ethylene Propylene Diene Monomer has high tensile strength

along with excellent resistance to punctures, UV radiation, weathering and in

certain formulations microbial attack. With a low co-efficient of thermal

expansion and contraction, EPDM is used in a wide range of temperatures and environments

but is commonly used in water and waste water treatment facilities.

Uncommon Lining materials will include:

Drinking Water Approved EPDM – We offer EPDM compounds to meet a wide range of European standards including WRAS, UBA, KTW, DWG, ACS and Belgaqua.

Viton – We supply genuine Chemours Viton for applications requiring high temperature and / or exception chemical resistance.

Food Quality Rubbers – All of our food quality materials are independently certified EC1935:EC2023 compliant, Nitrosamine Free, Animal Derived Ingredients Free, and Bisphenol Free. Available in Natural, Neoprene, Nitrile, EPDM, Silicone and Viton grades.

Metal Detectable Food Quality Rubber – We offer Metal Detectable Nitrile and Silicone to the same standards as our Food Quality Rubber compounds with the additional benefit of being metal detectable should any particles break off within the production process.

For more information or to obtain a quote on any of these compound and sheet materials contact ian.littleton@maclellanrubber.com

|

|

|