When we received a request

for an EPDM rubber

sheet that could be produced in a range of colours to support a

diverse manufacturing and assembly line, our interest was piqued as to how far

our technical team could push our manufacturing boundaries.

The client was looking to

use different coloured sheets on different production lines so that any

potential contamination from seal failure could be identified to a specific

section of the plant thereby allowing then to shut down on that area that was

affected and dramatically reduce down time.

The technicality of producing Rubber Sheet in colours is largely

dictated by the polymer type and how much the compound formulation is

acceptable of pigments; colour pigments are compounds in themselves and can

often act negatively with other chemicals during the curing process and

consequently detract from the desired characteristics of the formulation.

Requests to match Pantone references are quite common and, in

most cases, completely unattainable. Like so many materials where heat is

applied to produce the final product, controlling colours is limited to getting

it to the right shade rather than tightly controlling it.

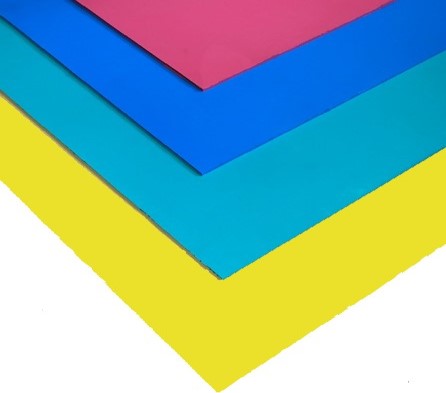

Challenged with providing seven clearly identifiable colours in

the same grade of EPDM,

our technical team undertook a programme of testing and development reviewing a

multitude of formulations and their reaction with colouring compounds and

chemicals.

Although laboratory development is proof of concept, we then had

to demonstrate that this could be scaled up to full production and give the

same quality results and technical characteristics in the cured rubber sheeting.

After a relatively short development and production trial

programme, we were able to submit our proposal based on a European manufactured

premium EPDM

Rubber Sheet offering the following colours: Blue, Yellow, Red, Green, Brown,

White and Black.

Following on site testing the client approved their use and orders

have followed with seals being manufactured by a waterjet cutter and

installation at site being achieved within less than 6 weeks.

Products Used

EU1935 Certified Food Quality EPDM

Application

Seals for Food, Drink, Biopharma production plant with

multiple lines producing the same products

Purpose

Enable rapid identification of fault area within the plant should

a seal fail and contaminate the process

Locations

UK,|

|

|