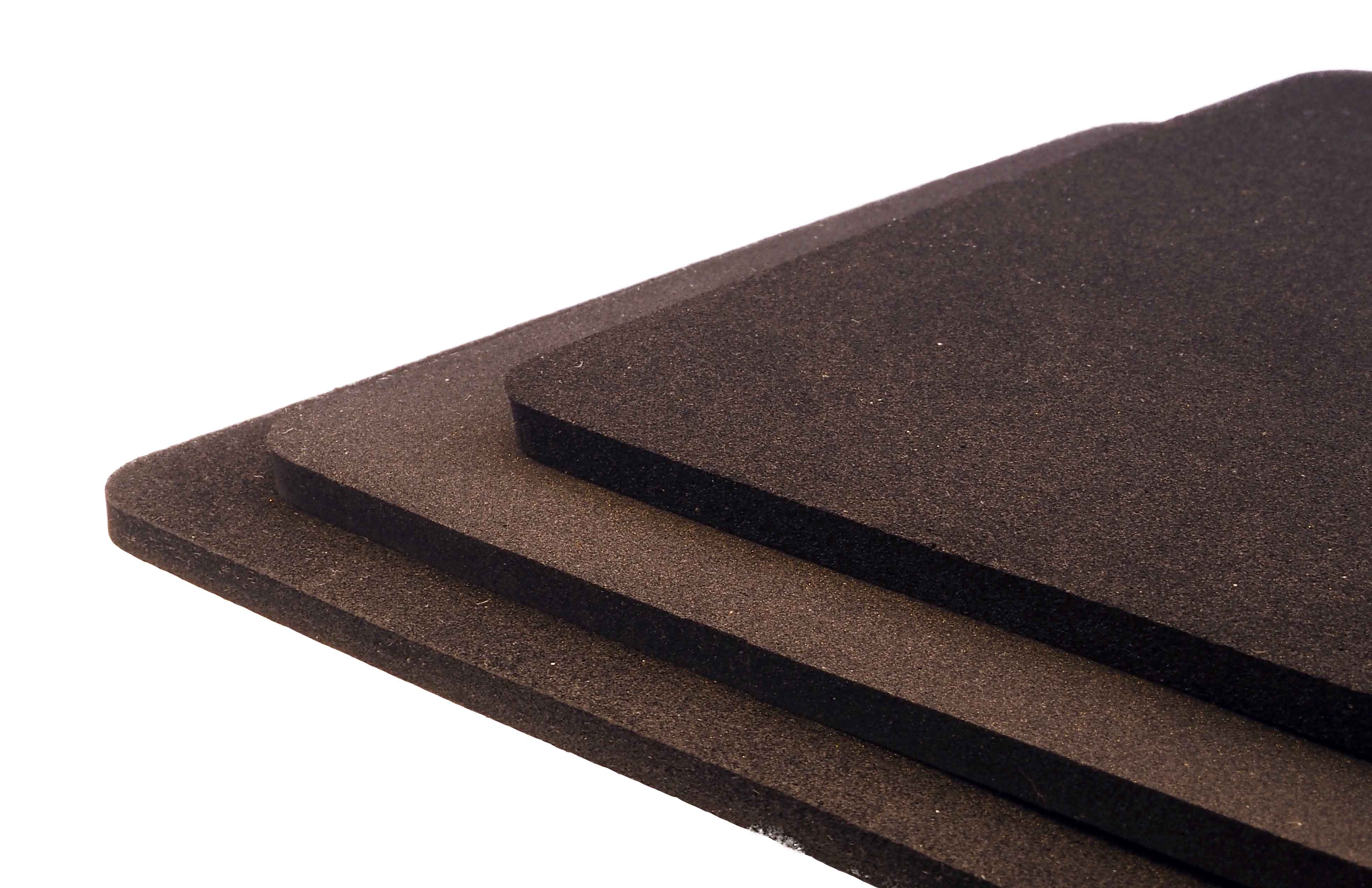

P581 Expanded Neoprene Sponge Rubber to UL94-HF1

PL581 is a high quality Neoprene Sponge with excellent Flame Retardant(conforming to UL94-HF1) & Weathering Properties. Typically used in applications such as Enclosures, Glazing Strips, and Expansion Joints in high technology industries including Automotive, Electronics and Construction.

Compression Set 25% Compression (22 Hours @ 23°C) 1/2 Hour Recovery

2-4 %

Compression Set 25% Compression (22 Hours @ 23°C) 1/2 Hour Recovery

2-4 %

Compression Set 50% Compression (22 Hours @ 23°C) 1/2 Hour Recovery

15-35 %

Compression Set 50% Compression (22 Hours @ 23°C) 1/2 Hour Recovery

15-35 %

Compression Stress/Strain - 25%

20-40 Kpa

Compression Stress/Strain - 25%

20-40 Kpa

Compression Stress/Strain - 50%

50-70 Kpa

Compression Stress/Strain - 50%

50-70 Kpa

Elongation at Break

150-200 %

Elongation at Break

150-200 %

FMVSS302 Pass Thickenss

3 mm

FMVSS302 Pass Thickenss

3 mm

Highest Recommended Working Temperature

80 °C

Highest Recommended Working Temperature

80 °C

Intermittent Working Temperature

100 °C

Intermittent Working Temperature

100 °C

Lowest Recommended Working Temperature

-40 °C

Lowest Recommended Working Temperature

-40 °C

Shore Hardness (Shore OO)

40-50 ° Shore

Shore Hardness (Shore OO)

40-50 ° Shore

Tensile Strength

530-600 Kpa

Tensile Strength

530-600 Kpa

UL94-HF1 Pass Thickness

3 mm

UL94-HF1 Pass Thickness

3 mm