MacLellan Rubber’s recently launched

Metal Detectable NBR sheet rubber and compound has already been specified by several major food processors in the Dairy, Fast Food and Confectionery sectors, and are working hard to have it recognised as the material of choice for replacement seals and gaskets in current operating equipment and with OEMs for new equipment installations.

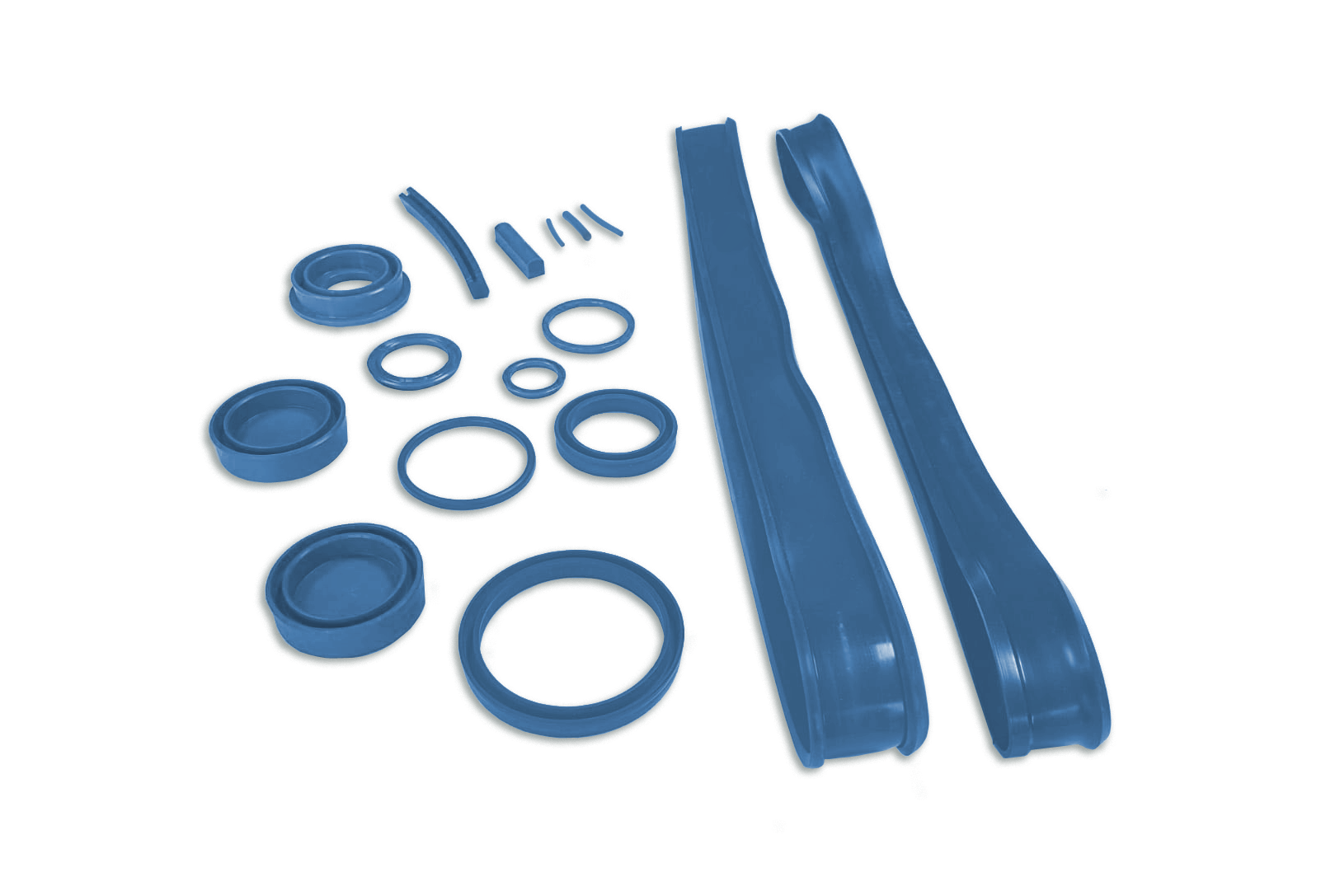

Gasket Cutters & End-Users See the Attraction

As well as being

Metal Detectable, the material meets a plethora of technical requirements and standards demanded by the Food, Drink, Pharmaceutical, Cosmetic and Biopharma industries including

EU1935:2004,

ADI and Nitrosamine Free.

An increasing number of gasket and seal manufacturers have placed significant stock orders to replace their current holdings of standard Food Quality materials or

Silicone MD product to meet their forecast demand for gaskets and seals and, having already pre-sold our first and second production batches, we are now increasing our capacity to keep pace with demand.

Simon Winfield, director of MacLellan Rubber, said: “As a technically superior product, this is a material that is not price sensitive. It offers unique features that are not available from other manufacturers of Food Quality materials and effectively it sells itself as demonstrated by the rapid uptake by those MacLellan customers with a significant position in the supply of seals and gaskets to the FoodSafe industries.”

The new

Blue Metal Detectable Nitrile rubber is available in a variety of formats, either cured or uncured, with full manufacturing batch testing and release certificates, as required. OEMs, MROs, seal manufacturers and end users can request material information by calling the team on

01902 307711.